Multi-lift Use

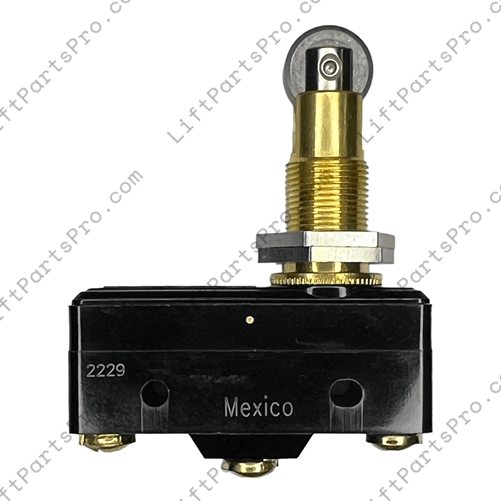

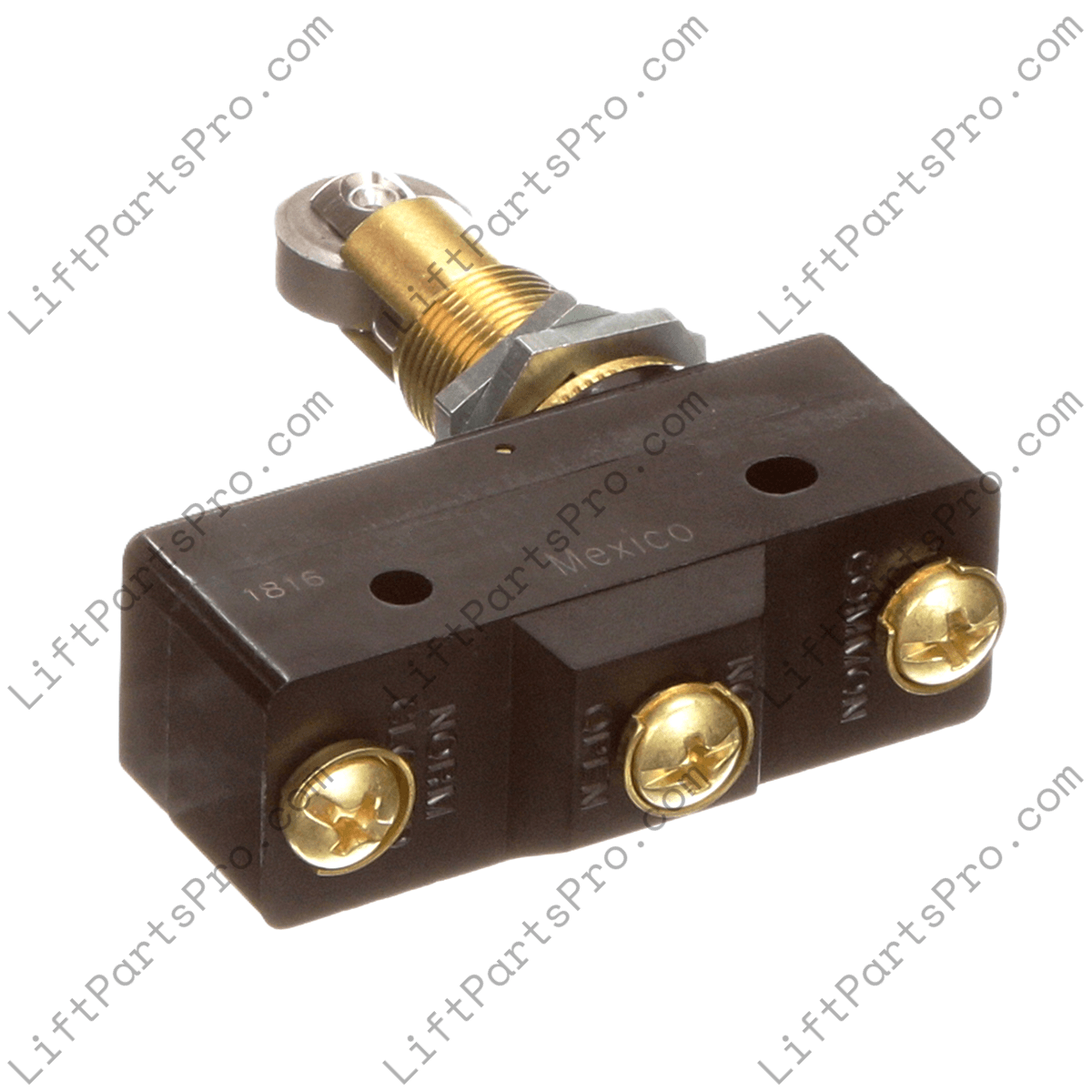

Lift Brake Switch – Roller Plunger Microswitch SPDT 15A with Screw Terminals

Lift Brake Switch – Roller Plunger Microswitch SPDT 15A with Screw Terminals

🔄 Backorder Available

This item is available for backorder. Estimated lead time is 8 to 14 business days. We’ll send an update once your order is confirmed and provide tracking when it ships.

SKU: LS.BRK.15A

Condition: New

Couldn't load pickup availability

Heavy-duty SPDT roller wheel brake switch for elevators and lifts; rated 15A, with screw terminals and long mechanical life.

This high-performance microswitch is commonly used as a brake switch in lift and elevator systems. It features a roller plunger actuator for precise mechanical triggering and a single-pole, double-throw (SPDT) contact configuration. Built with durable materials and a long mechanical cycle life, this switch is suitable for demanding control applications. The body includes panel mounting holes and screw-style terminals for secure electrical connection. Ideal as a replacement in existing systems that require a mechanical roller-style limit switch.

Specifications

- Contact Configuration: SPDT (Single Pole Double Throw)

- Current Rating: 15A

- Voltage Rating: Up to 480 VAC or 250 VDC

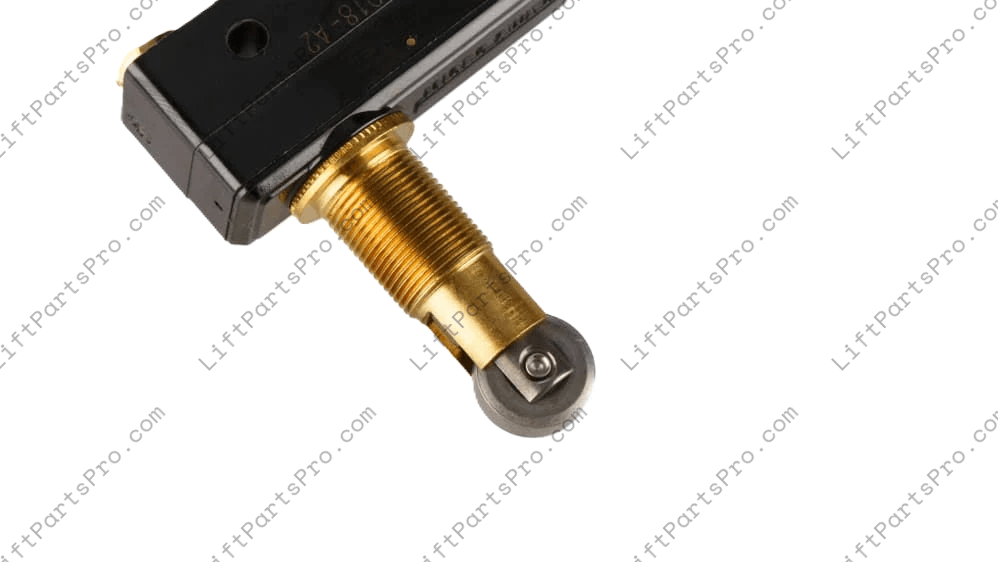

- Actuator Type: Roller Plunger

- Termination: Screw Terminals

- Operating Force: ~2.5 to 3.6 N

- Release Force: ≥1.11 N

- Pretravel: ≤0.38 mm

- Overtravel: ≥3.56 mm

- Differential Travel: ~0.01–0.05 mm

- Mechanical Life: 20 million cycles (typical)

- Operating Temperature: −55 °C to +85 °C

- Mounting: Panel mount holes on body

Overall Dimensions

- Length: 49.3 mm (≈ 1.94 in)

- Width: 17.5 mm (≈ 0.69 in)

- Height: 24.1 mm (≈ 0.95 in)

Mounting Details

- Mounting centers (distance between mounting holes): 25.4 mm (1.00 in)

- Mounting screw hole size: accepts screws or pins of 3.53 mm diameter (≈ 0.139 in)

- Approximate weight: 63.5 g (≈ 0.14 lb)

This switch is engineered for precision and durability in elevator brake or control systems. Always verify mechanical and electrical compatibility before use. Installation should be performed by qualified personnel in accordance with safety and code requirements.

Share